Most engineers treat anti-surge valves as standalone components. That's mistake #1. It's the entire valve + piping system that dictates performance and reliability.

Here are 4 field-tested insights that challenge conventional wisdom:

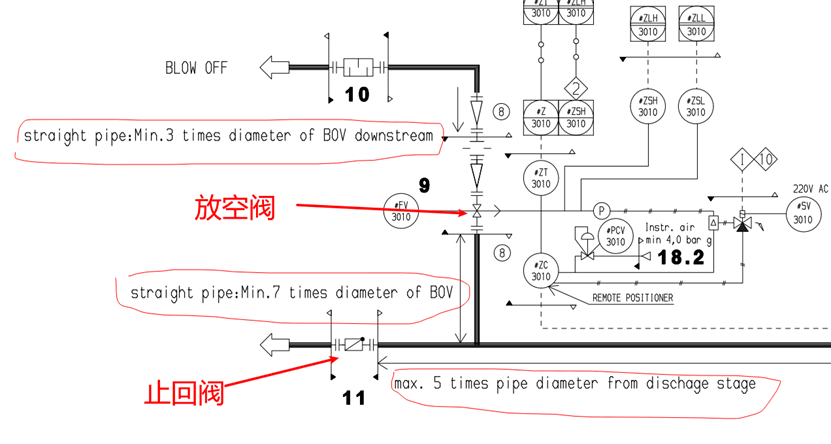

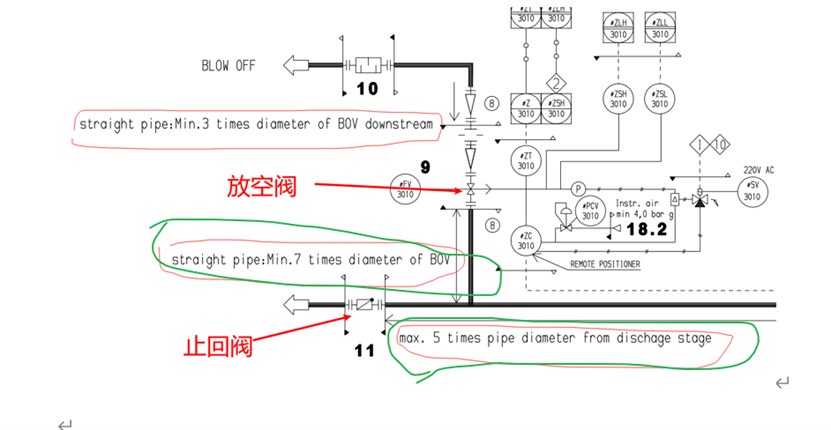

1. Straight Pipe Runs: The 7D vs 4D Reality Check

Two major compressor OEMs, two different specs:

OEM A: 7D upstream, 3D downstream

OEM B: 4D upstream, 8D downstream

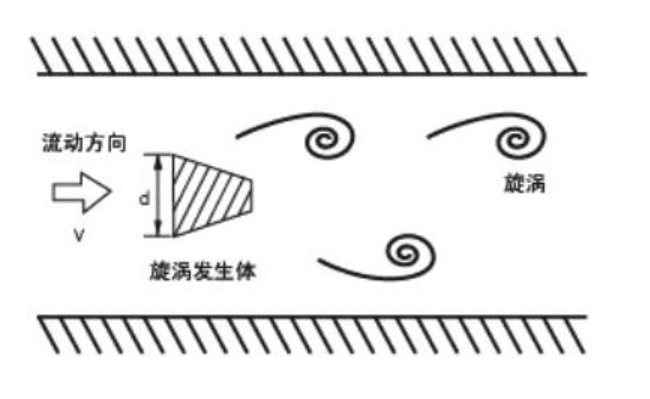

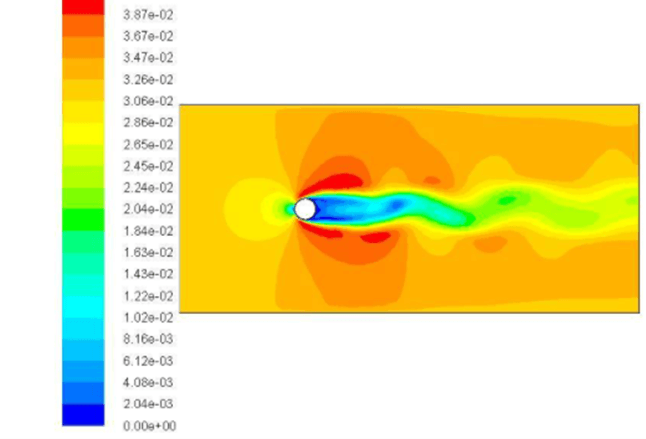

Who's right? Fluid dynamics (Karman vortex street principle) shows valve trim creates turbulence downstream, not upstream—like a bridge pier disrupting water flow.

Verdict: Prioritize downstream length. 4D/8D wins.

2. The "One-Second Rule" for Compressor Proximity

Some specs limit the volume between compressor discharge, check valve, and anti-surge valve to <1 second's displacement. Why? To outrun the surge zone before it destabilizes.

Most manufacturers don't mention this. Consider it a best practice.

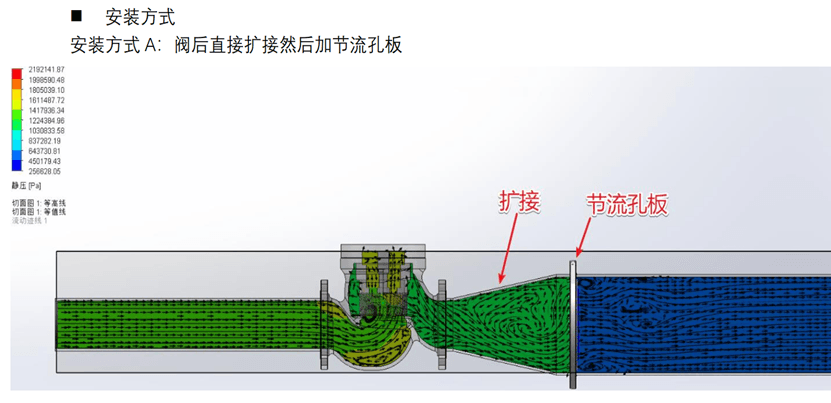

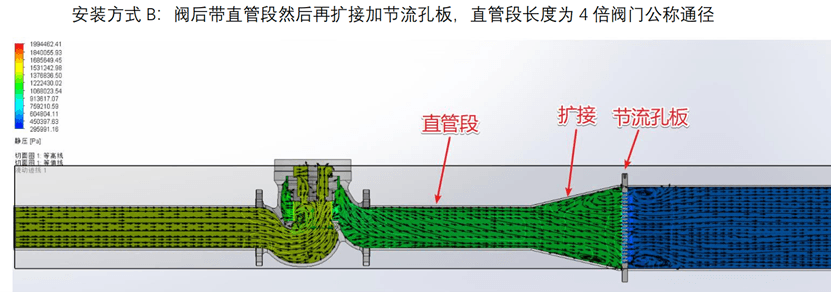

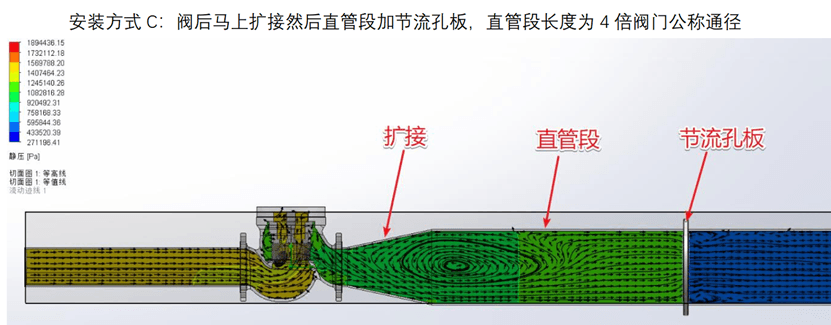

3. Orifice Plate Location: Downstream buffer

Downstream the anti-surge valve, need a straight pipe run as a buffer. CFD analysis shows this amplifies turbulence and wrecks control stability.

Correct sequence: Valve → straight pipe run → orifice plate. That downstream buffer is critical for flow stabilization.

4. Orifice Design: When Vibration Goes Off the Charts

Case study: Standard single-hole plate caused pipeline vibration to spike dangerously 5D downstream. Solution? Multi-hole plate + extended straight pipe. Problem solved.

Question for the field: What's your experience with anti-surge piping layouts? Have vibration issues forced you to redesign?